One Of The Best Info About What Is The Principle Of Mechanical Sensor

Proximity Sensors How It Works, Application & Advantages

Unlocking the Secrets of Mechanical Sensors

1. What Exactly Is a Mechanical Sensor?

Alright, let's dive into the fascinating world of mechanical sensors! Imagine a device that can "feel" the physical world — pressure, movement, position, even acceleration. That's essentially what a mechanical sensor does. Its like giving your digital devices a sense of touch! These sensors convert mechanical forces into measurable electrical signals. Think of it like a translator between the physical and digital realms. Pretty cool, right?

Now, you might be thinking, "Okay, but where do I see these things in action?" Everywhere, my friend! From the anti-lock braking system (ABS) in your car (sensing wheel speed and preventing skidding) to the simple button you push on your microwave (detecting pressure), mechanical sensors are working behind the scenes. Even those fancy touchscreen devices you cant live without rely on detecting your finger's pressure. They are silent guardians, ensuring things work smoothly and safely.

Essentially, the core principle involves a physical change — a bend, a stretch, a squeeze — that's then converted into an electrical signal. This signal is then processed to provide valuable information about the mechanical input. It's a clever little dance between physics and electronics. It's like a tiny Rube Goldberg machine, but instead of flipping pancakes, it's providing critical data.

So, what makes a mechanical sensor "mechanical?" The key is that the initial sensing element is a physical component that deforms or moves in response to the measured quantity. This distinguishes them from other types of sensors, like temperature sensors, which rely on changes in electrical properties due to temperature. It's all about that initial physical interaction! That initial "Ouch, something's pushing on me!" moment for the sensor.

Water Sensor Working Principle

The Nitty-Gritty

2. Diving Deeper into the Mechanisms

Okay, we know what they do, but let's peek under the hood. Most mechanical sensors work by changing an electrical property, like resistance, capacitance, or inductance, in response to a mechanical stimulus. Think of it as a dimmer switch for electricity, but instead of a knob, you're using pressure or movement to control the flow. The more pressure, the more (or less, depending on the design) electricity flows.

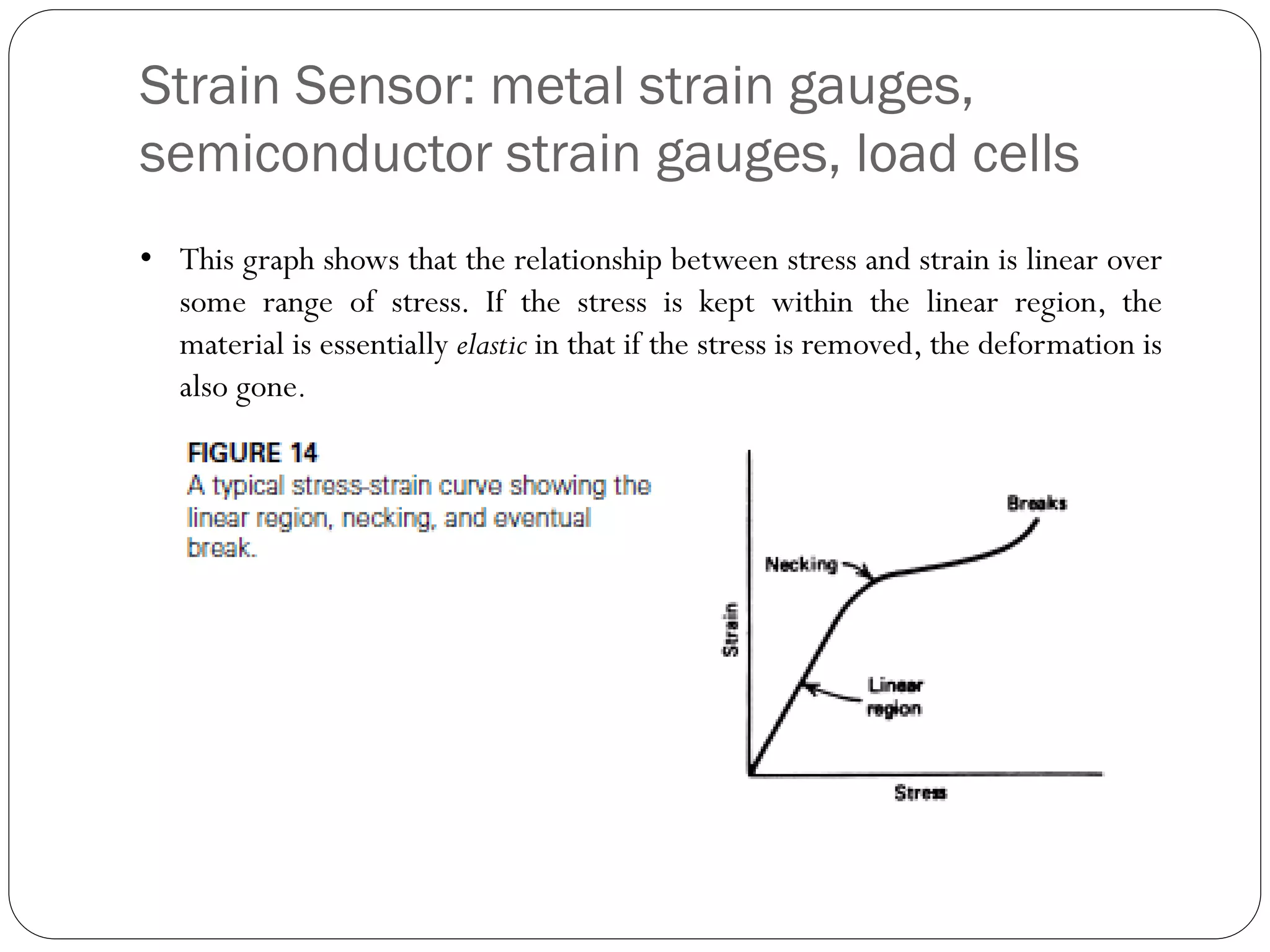

For instance, a strain gauge, a very common type of mechanical sensor, works by changing its electrical resistance when it's stretched or compressed. These tiny devices are often bonded to surfaces to measure stress and strain in materials. Imagine tiny little electrical hairs that report back how much something is bending or stretching. Pretty neat, huh? They are commonly used in weighing scales and aerospace applications.

Another example is a capacitive pressure sensor. Here, the distance between two conductive plates changes with applied pressure, altering the capacitance. This change in capacitance can be measured and correlated to the applied pressure. Think of it as a tiny capacitor sandwich where squeezing the filling (the space between the plates) changes how much electrical charge it can store. Simple, yet effective.

And then there are inductive proximity sensors, which detect the presence of an object without physical contact. These sensors use a coil to generate an electromagnetic field. When a metallic object enters the field, it changes the coil's inductance. This change can be detected and used to trigger an action. It's like an invisible electrical tripwire that senses metal objects getting too close. Used everywhere from assembly lines to security systems!

Mechanical Sensors

Types of Mechanical Sensors

3. From Pressure to Position, We've Got You Covered

Mechanical sensors come in a dazzling array of types, each tailored for specific tasks. Pressure sensors, for measuring force per unit area, are widely used in automotive, medical, and industrial applications. They're the unsung heroes ensuring your car's tire pressure is just right or monitoring blood pressure during surgery.

Accelerometers, which measure acceleration, are found in everything from smartphones (for screen rotation) to aerospace guidance systems. They're the reason your phone knows which way is up and the reason rockets stay on course. They are also crucial in detecting earthquakes!

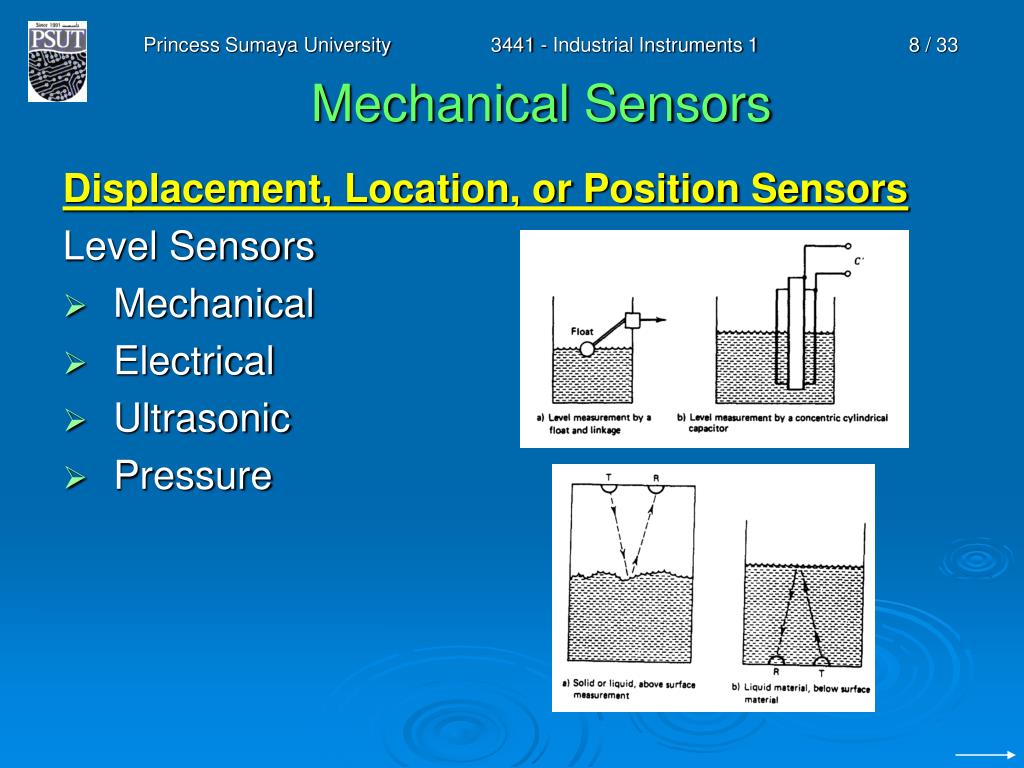

Position sensors, also known as displacement sensors, determine the location of an object. They're used in robotics, manufacturing, and even in those fancy adjustable office chairs. Think of them as the eyes of automation, guiding robotic arms and ensuring your chair is at the perfect height. Common types include potentiometers, LVDTs (Linear Variable Differential Transformers) and optical encoders.

Flow sensors measure the rate at which a fluid (liquid or gas) is moving. They are essential in industries like oil and gas, water treatment, and HVAC systems. They ensure that the right amount of fluid is flowing through your pipes and that your air conditioning is keeping you cool. Also key to monitoring patient breathing rates in healthcare!

Why Mechanical Sensors Matter

4. The Unsung Heroes of Modern Technology

Mechanical sensors are so prevalent that its easy to take them for granted. But imagine a world without them! Your car wouldn't have ABS, your smartphone wouldn't know which way is up, and robots wouldn't be able to perform precise tasks. Chaos would ensue! Seriously, they're the bedrock of countless technologies.

In the automotive industry, mechanical sensors are critical for safety and performance. They monitor everything from tire pressure and engine temperature to brake performance and airbag deployment. They're like the nervous system of your car, constantly monitoring and adjusting to ensure a smooth and safe ride.

In healthcare, mechanical sensors are used in medical devices like blood pressure monitors, ventilators, and infusion pumps. They provide crucial data that helps doctors diagnose and treat patients. They are literally lifesavers, ensuring that medical equipment is working correctly and delivering the right doses of medication.

And in industrial automation, mechanical sensors are essential for controlling robotic arms, monitoring machine performance, and ensuring product quality. They enable factories to operate efficiently and produce high-quality goods. They are the brains behind the automated processes that keep our economy humming.

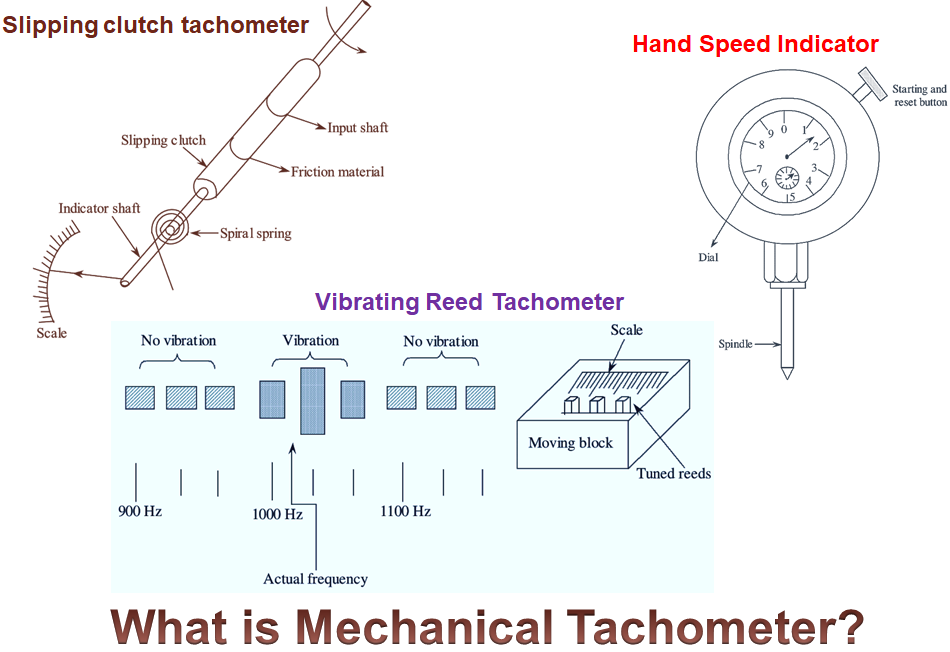

What Is Mechanical Tachometer? Working Principle, Types & Diagram

Future Trends in Mechanical Sensors

5. What's on the Horizon?

The field of mechanical sensors is constantly evolving, with new materials, designs, and applications emerging all the time. One exciting trend is the development of micro-electromechanical systems (MEMS), which are tiny sensors fabricated using microfabrication techniques. These miniature sensors are incredibly small, lightweight, and energy-efficient, making them ideal for wearable devices, implantable medical devices, and other applications where size and power are critical. Smaller, smarter, and more powerful sensors are the future.

Another trend is the integration of mechanical sensors with wireless communication technologies, enabling remote monitoring and control. This allows for real-time data collection and analysis, improving efficiency and reducing costs. Imagine monitoring the structural health of a bridge from your smartphone, or controlling your home's HVAC system from anywhere in the world.

Self-powered sensors, which harvest energy from their environment (e.g., vibration, light, or heat), are also gaining traction. These sensors eliminate the need for batteries, making them ideal for remote and hard-to-reach locations. No more changing batteries in those hard-to-reach places! A real game-changer for environmental monitoring and industrial applications.

Finally, artificial intelligence (AI) is being used to improve the performance of mechanical sensors. AI algorithms can analyze sensor data to detect anomalies, predict failures, and optimize performance. This allows for more efficient and reliable operation of systems that rely on mechanical sensors. The combination of smart sensors and smart algorithms is unlocking new possibilities!