Neat Info About How To Control A MOSFET

Power Mosfet Motor Control

Understanding the MOSFET

1. What Exactly Is a MOSFET? (In Plain English)

So, you're diving into the world of electronics and keep hearing about MOSFETs. Don't let the name intimidate you! A MOSFET, or Metal-Oxide-Semiconductor Field-Effect Transistor, is basically a tiny electronic switch. Think of it as a gatekeeper controlling the flow of electricity in a circuit. Unlike a regular switch you flip with your finger, a MOSFET is controlled by voltage applied to its "gate" terminal.

Imagine a water tap. The gate is like the handle. Turn the handle (apply voltage to the gate), and water (electricity) flows. The more you turn the handle, the more water flows. Simple, right? This ability to control current flow with voltage is what makes MOSFETs so versatile in everything from power supplies to amplifiers.

Now, there are two main "flavors" of MOSFETs: N-channel and P-channel. N-channel MOSFETs turn on when you apply a positive voltage to the gate, while P-channel MOSFETs turn on when you apply a negative voltage. This difference allows for some really clever circuit designs, letting you choose the best type for your specific needs. Getting this choice wrong is like trying to use a left-handed glove on your right hand — functional, but hardly ideal.

One last crucial piece of the puzzle: MOSFETs have three terminals: the Gate (where you apply the control voltage), the Drain (where the current enters), and the Source (where the current exits). Keep these in mind, and you're already well on your way to mastering how to control a MOSFET! It's the difference between correctly wiring a circuit and accidentally releasing the magic smoke.

Applying Voltage

2. Voltage is the Controller

Alright, we know MOSFETs are voltage-controlled switches, but how do we actually use that to our advantage? The core principle is straightforward: Apply the correct voltage to the gate, and the MOSFET switches on, allowing current to flow between the drain and the source. Remove the voltage (or apply the opposite polarity voltage for P-channel MOSFETs), and the switch turns off, blocking current flow.

But here's the catch: MOSFETs aren't perfect. They require a certain minimum voltage to switch on fully. This voltage is called the "threshold voltage" (Vth), and it's a crucial specification to consider. Think of it like needing a certain amount of pressure to open that water tap we talked about earlier. Below that pressure, you might get a trickle, but not a full flow. If you dont know this value, you'll be scratching your head wondering why your circuit isn't working properly.

The voltage applied to the gate should be within the manufacturer's specified range. Applying too much voltage can damage the MOSFET permanently. Treat it like a delicate flower and not a sledgehammer. Using a simple resistor voltage divider is one way to achieve the appropriate voltage. The resistor values can be adjusted to set the correct voltage for the gate.

Furthermore, how quickly you apply the voltage to the gate also matters. Rapid switching can cause issues like ringing or overshoot, which can lead to unexpected behavior in your circuit. To mitigate these effects, you can use gate resistors and other techniques to smooth out the switching transitions, or simply ensure your power supply has the current to support the application.

Connecting Mosfets In Series

Choosing the Right Resistor

3. Resistors and Voltage

We mentioned resistors, but let's delve deeper into their role in controlling MOSFETs. Resistors are often used to limit the current flowing into the gate, protecting it from excessive voltage or current. They can also be used to create voltage dividers, providing the precise voltage needed to turn the MOSFET on or off. A resistor can also be used to ensure the MOSFET is fully turned off and prevents floating voltages.

Selecting the right resistor value is crucial. Too low a resistance, and you might not adequately protect the gate. Too high a resistance, and the MOSFET might not switch on fully, leading to inefficient operation. The ideal resistance depends on the specific MOSFET, the applied voltage, and the desired switching speed. Calculate, calculate, calculate — or risk a fiery end to your MOSFET's short life. This is where Ohm's Law becomes your closest friend!

Another important consideration is the power rating of the resistor. Resistors dissipate power as heat, and if the resistor is undersized, it can overheat and fail. Calculate the power dissipation based on the voltage across the resistor and the current flowing through it. Choose a resistor with a power rating significantly higher than the calculated dissipation to ensure reliable operation. It's like buying shoes that are slightly too big rather than too small — comfort is key!

Consider using a pull-up or pull-down resistor on the gate. A pull-up resistor connects the gate to a high voltage, ensuring the MOSFET is normally off. A pull-down resistor connects the gate to ground, ensuring the MOSFET is normally on. These resistors provide a default state for the MOSFET, preventing it from floating and potentially switching on or off randomly. These help to prevent unexpected and erratic behavior of the MOSFET due to noise or static electricity.

Pulse Width Modulation (PWM)

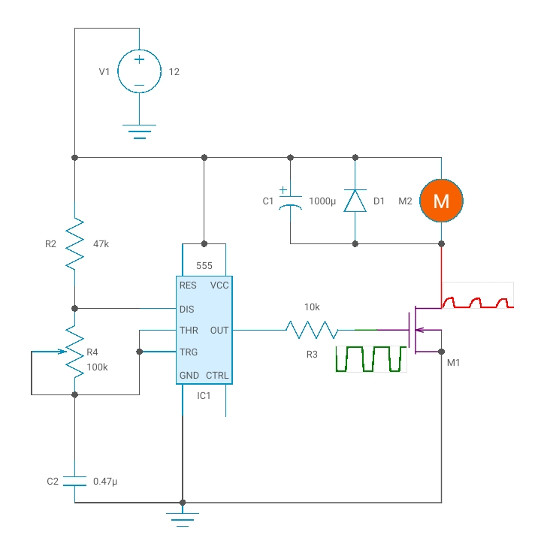

4. Modulating for Precision

Want even more control over your MOSFET? Enter Pulse Width Modulation (PWM). PWM is a technique that allows you to vary the average voltage applied to the MOSFET by rapidly switching it on and off. The "duty cycle," or the percentage of time the MOSFET is on during each cycle, determines the effective voltage. With PWM, the MOSFET is switched on and off at a rate faster than the load can respond to, this allows a varying amount of power to be delivered to the load based on the percentage of on time.

Imagine dimming a lightbulb. Instead of continuously reducing the voltage, you're rapidly flickering the light on and off. The faster the flickering, the less noticeable it becomes, and the perceived brightness depends on how long the light is on during each flicker cycle. PWM is very efficient for motor control. It is also used in LED dimming circuits because of its ability to finely control power output.

PWM is particularly useful in applications like motor speed control, LED dimming, and creating analog outputs from digital circuits. By carefully adjusting the duty cycle, you can achieve precise control over the output. Many microcontrollers have dedicated PWM modules, making it easy to generate PWM signals without writing complex code. The microcontroller switches the voltage on and off with great precision.

When using PWM, it's essential to choose an appropriate switching frequency. Too low a frequency can cause flickering or audible noise, while too high a frequency can lead to switching losses in the MOSFET. The optimal frequency depends on the application and the characteristics of the MOSFET. It's about finding that sweet spot where performance and efficiency meet, similar to tuning a musical instrument for the perfect sound.

Thermistor MOSFET Fan Controller (circuit Operation) Part 1 YouTube

Practical Tips and Common Pitfalls

5. Avoiding the Dreaded Magic Smoke

Now that you understand the theory, let's cover some practical tips to avoid common pitfalls. First, always double-check your wiring. A misplaced wire can lead to catastrophic failures. Verify the pinout of your MOSFET and ensure you're connecting the gate, drain, and source to the correct points in your circuit. Use a multimeter to confirm the voltages and currents are within the expected ranges. Measure twice, cut once — a mantra for electronics enthusiasts everywhere.

Second, pay attention to heat. MOSFETs generate heat when switching, especially at high frequencies. Use heat sinks to dissipate the heat and prevent the MOSFET from overheating. If your MOSFET is getting too hot to touch, it's a sign that something is wrong. Overheating can dramatically shorten the lifespan of the MOSFET or lead to immediate failure. Consider using a fan to enhance cooling in demanding applications.

Third, protect your MOSFET from electrostatic discharge (ESD). ESD can damage the gate and cause premature failure. Use ESD-safe equipment and grounding techniques when handling MOSFETs. Ground yourself before touching any electronic components, and store MOSFETs in antistatic bags. Prevention is always better than cure, especially when dealing with sensitive electronics.

Finally, always consult the datasheet. The datasheet contains crucial information about the MOSFET's specifications, including the threshold voltage, maximum voltage and current ratings, and thermal characteristics. Understanding these specifications is essential for designing a reliable and efficient circuit. Treat the datasheet as your holy grail of MOSFET knowledge. This way you avoid issues and have a properly working design that utilizes the MOSFETs to its maximum.

FAQ

6. Q

A: Applying excessive voltage to the gate can damage the gate-oxide layer within the MOSFET. This can lead to permanent degradation of the MOSFET's performance or complete failure. Treat the gate voltage limits with respect. Think of it like blowing out a speaker by turning the volume up too high.

7. Q

A: Consider several factors, including the voltage and current requirements of your circuit, the desired switching speed, and the operating temperature. Consult the datasheet to ensure the MOSFET meets your specifications. There are literally thousands of MOSFETs out there. Getting familiar with selecting components based on your circuit is crucial to electronics.

8. Q

A: Yes, in the linear region of operation, a MOSFET can act as a voltage-controlled resistor. However, it's generally not as accurate or linear as a dedicated potentiometer. This is most likely not the ideal solution but in a pinch may work in some applications. Think of this as a bonus feature of the MOSFET rather than its primary intended use.