Marvelous Tips About What Is The Bill Of Material Items

Bill Of Materials PDF

Unlocking the Secrets of the Bill of Material Items

1. What Exactly Are We Talking About?

Ever wondered how a company manages to build, say, a smartphone? It's not magic, though it might seem like it sometimes! The secret lies in a meticulously crafted document called a Bill of Material, or BOM. Think of it as a recipe, but instead of flour and sugar, we're talking about circuit boards, screens, screws, and everything else that goes into the final product. Without it, things would descend into chaos pretty quickly, like trying to bake a cake without knowing what ingredients you need.

Essentially, a BOM is a comprehensive list of all the raw materials, components, assemblies, and quantities required to manufacture a product. It's the linchpin of production planning, ensuring everyone knows what they need, how much they need, and when they need it. It's also quite useful in predicting costs, which, lets be honest, is important.

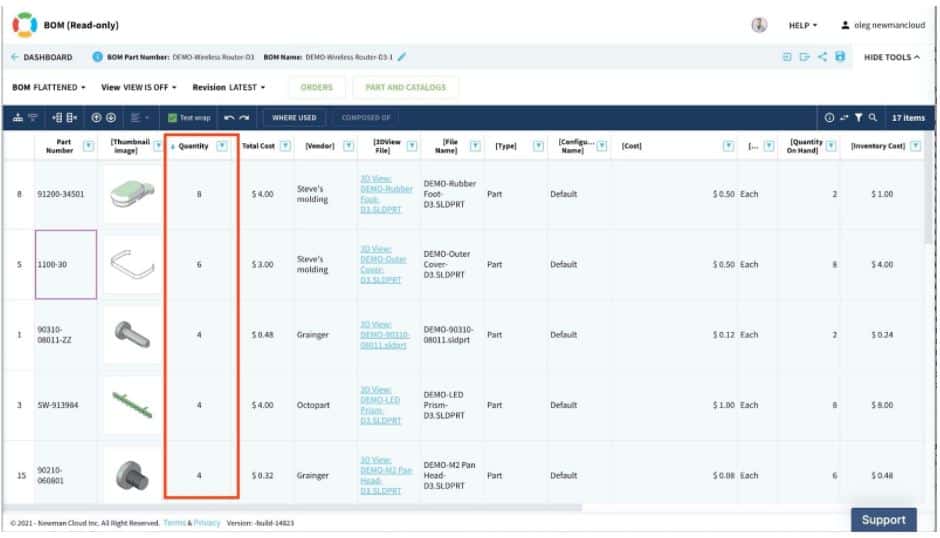

A well-structured BOM isnt just a laundry list. It includes details like part numbers, descriptions, vendor information, and even notes on assembly instructions. Its a living document, constantly updated and refined as products evolve. Imagine trying to keep track of thousands of parts manually! That sounds like a nightmare that even spreadsheets couldn't solve!

In short, if you're dealing with any sort of manufacturing, a Bill of Material is non-negotiable. It's the cornerstone of efficient production, cost control, and overall quality. Think of it as the difference between a well-oiled machine and a rusty contraption held together by duct tape. And trust me, you want the well-oiled machine.

![FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD] FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]](https://www.dailylifedocs.com/wp-content/uploads/2022/03/BOM-Template-2578919-1024x752.jpg)

FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]

Dissecting the Anatomy of a BOM

2. Components and Structure

So, what does a Bill of Material actually look like? Well, it's not a single, monolithic block of text. Instead, it's usually structured hierarchically, reflecting how a product is assembled. At the top level, you have the finished product itself. Beneath that, you have the major assemblies, and then the individual components that make up those assemblies. It's like a family tree, but for gadgets!

Each item in the BOM is usually assigned a unique part number, which helps to identify it unambiguously. You'll also find a description of the item, specifying what it is and, perhaps, its key characteristics. The quantity field tells you how many of each item are needed to build one unit of the product. This seems obvious, but you'd be surprised how many errors can creep in without proper management.

Beyond the basics, a BOM often includes information about the supplier or vendor for each item, as well as any relevant costs. Some BOMs might even incorporate manufacturing instructions or links to CAD drawings. Think of it as the ultimate reference guide for bringing a product to life.

Different types of BOMs exist, tailored to specific needs. An Engineering BOM (EBOM) focuses on the design aspect, while a Manufacturing BOM (MBOM) is geared toward production. There are also Sales BOMs (SBOMs) and Configurable BOMs (CBOMs). All of these variations aim to optimize the process of making and selling products.

Bill Of Materials Or Bills Material Notebase

Why Bother With a Detailed BOM?

3. The Benefits of Being Organized

Okay, so creating and maintaining a Bill of Material sounds like a lot of work. Is it really worth the effort? The answer, unequivocally, is yes! A well-managed BOM brings a host of benefits to the table, impacting everything from production efficiency to cost control.

First and foremost, it streamlines the procurement process. By having a clear list of required materials, companies can order the right quantities at the right time, avoiding stockouts and delays. Imagine trying to assemble a bicycle only to discover you're missing a pedal! A proper BOM prevents such scenarios.

BOMs also play a crucial role in cost estimation and control. By knowing the cost of each component, companies can accurately calculate the overall cost of the product and identify areas for potential savings. Maybe there's a cheaper alternative for that particular screw, or a different supplier who offers better rates. The BOM gives you the insights to make informed decisions.

Furthermore, a BOM facilitates better communication and collaboration across different departments, like engineering, purchasing, and manufacturing. Everyone is working from the same page, reducing the risk of misunderstandings and errors. Imagine trying to build a house if the architect, the builder, and the plumber were all using different sets of blueprints. It would be total chaos!

Ultimately, a detailed and up-to-date BOM contributes to improved product quality and reliability. By ensuring that the right components are used in the right way, companies can minimize defects and create products that meet customer expectations. And happy customers, as we all know, are the key to long-term success.

Bill of Material Items in Action

4. From Smartphones to Automobiles

Let's move beyond theory and consider some real-world examples of how Bill of Material items are used in practice. Take, for instance, the smartphone industry. A modern smartphone is an incredibly complex device, comprising hundreds of individual components, from the processor and memory chips to the display screen and camera modules. Each of these components is meticulously tracked within the BOM.

Similarly, the automotive industry relies heavily on BOMs to manage the thousands of parts that go into a car. From the engine and transmission to the seats and dashboard, every single item is listed and tracked. The BOM helps automakers ensure that they have the right parts available at the right time, minimizing production delays and ensuring that the vehicles meet quality standards.

But BOMs aren't just for complex products like smartphones and cars. They're also used in the manufacturing of simpler items, such as furniture, appliances, and even clothing. In fact, any product that requires multiple components or materials to be assembled is a good candidate for a BOM.

Consider a simple wooden chair. Even a seemingly basic product like this requires a BOM to track the wooden boards, screws, glue, and any other materials needed for construction. Without a BOM, it would be difficult to ensure that the chair is built correctly and efficiently.

Free Engineering Bill Of Materials Templates For Google Sheets And

Future Trends

5. What's Next for Bills of Material?

The world of manufacturing is constantly evolving, and BOM management is no exception. As technology advances and new challenges emerge, we can expect to see further innovations in how BOMs are created, managed, and utilized. So, what does the future hold for this critical document?

One key trend is the increasing integration of BOMs with other enterprise systems, such as Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) software. This integration allows for seamless data flow across different departments, improving efficiency and reducing the risk of errors. Imagine a world where the BOM automatically updates as design changes are made, instantly alerting the purchasing department to order new components!

Another trend is the growing use of cloud-based BOM management solutions. These solutions offer greater flexibility and scalability compared to traditional on-premise systems, allowing companies to easily collaborate and share data across different locations. This is especially beneficial for companies with global supply chains.

Furthermore, we can expect to see increased use of artificial intelligence (AI) and machine learning (ML) in BOM management. AI can be used to automate tasks such as data entry and validation, while ML can be used to predict demand and optimize inventory levels. Imagine a BOM that can automatically identify potential supply chain disruptions and suggest alternative suppliers!

BILL OF MATERIALS FOR THE CODE IS OFF MARK AND FULL ERRORS

FAQ

6. Your Questions Answered

Still have some burning questions about Bill of Material items? Let's tackle some frequently asked questions to clear up any lingering confusion.

7. Q

A: Great question! An Engineering BOM (EBOM) is primarily used by the engineering department during the design phase. It focuses on the functional aspects of the product and may include items that are not directly used in manufacturing. A Manufacturing BOM (MBOM), on the other hand, is specifically tailored for the manufacturing process. It includes only the items needed to build the product and provides detailed instructions on how to assemble it.8. Q

A: Absolutely! While BOMs are most commonly associated with physical products, they can also be used to define the components and steps involved in delivering a service. For example, a BOM for a consulting service might include items such as consulting hours, travel expenses, and software licenses. It's all about breaking down the service into its constituent parts.9. Q

A: That depends on the rate of change in your product design and manufacturing process. If you're constantly making changes to your products, then you'll need to update your BOMs frequently. However, even if your products are relatively stable, it's a good idea to review your BOMs periodically to ensure they are accurate and up-to-date. Think of it like giving your car a regular tune-up to keep it running smoothly. Plus, mistakes can happen, prices can fluctuate, and suppliers can change. So regular review is a must!