Nice Tips About How Do You Open Connector Pins

Delving into the Delicate Art of Connector Pin Extraction

1. Understanding the Challenge

Ever stared at a connector, those tiny pins nestled inside, and felt a surge of frustration? You're not alone! Whether you're repairing electronics, working on a DIY project, or just trying to salvage a cable, knowing how to safely extract connector pins is a valuable skill. It's a bit like brain surgery for electronics, only (hopefully) less messy.

But why bother learning? Because those little pins can be surprisingly fragile. Yanking them out with brute force is a recipe for bent pins, damaged connectors, and a whole lot of wasted time. Trust me, I've been there. My initial attempts looked more like a wrestling match than a delicate procedure. So, let's learn how to do it right, shall we?

Think of it this way: each connector pin has a story. Its connected to something, sending a signal, completing a circuit. By understanding the pin's purpose, you appreciate its importance. The right tools and methods become essential to preserving those vital connections. No more barbaric yanking!

This isn't just about avoiding damage, its about respecting the engineering that went into creating these connectors in the first place. They're designed for specific purposes, and treating them with care ensures your projects will function reliably. Plus, you get to feel like a miniature electronics surgeon, which is pretty cool.

2. Gathering Your Arsenal

Before we dive into the actual extraction process, let's talk tools. Just like a surgeon needs their instruments, you'll need a few key items to make this process smooth and painless. You wouldn't try to remove a splinter with a hammer, would you? Same principle applies here.

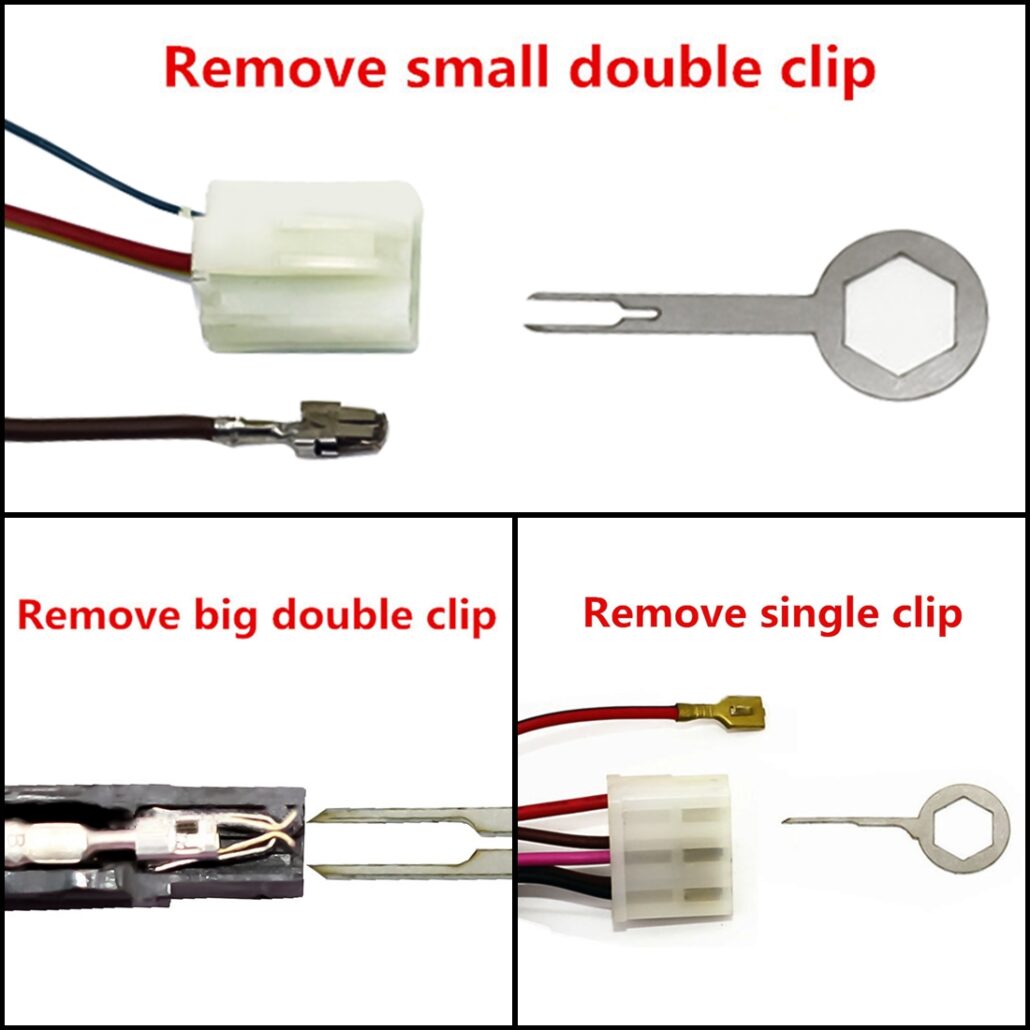

The most important tool is a pin extraction tool, often called a "depinning tool." These come in various shapes and sizes, designed for different types of connectors. Using the correct one is absolutely vital. Trying to use a paperclip (I know, the temptation is strong) often leads to bent pins and regret. Invest in a decent set; your future self will thank you.

Besides the depinning tool, a good magnifying glass or headset magnifier is a lifesaver. Those pins are tiny! Being able to see exactly what you're doing will significantly reduce the risk of damaging anything. Good lighting is also crucial; working in a dimly lit area is like trying to perform surgery in a cave.

Finally, a pair of tweezers can be handy for gently removing the pin once it's released. Opt for fine-tipped tweezers for precise manipulation. And while it might seem obvious, having a well-lit workspace is crucial for visibility and accuracy. You don't want to be fumbling around in the dark, hoping for the best! Think of your workspace as your operating room; keep it clean and organized.

Front Panel 9 Pin Connector At Glen Kyser Blog

The Art of Release

3. Identifying the Locking Mechanism

Okay, so you've got your tools and your magnifying glass. Now comes the slightly tricky part: understanding how the connector's locking mechanism works. Most connectors use a small plastic tab or metal spring that holds the pin in place. This is what prevents the pin from simply falling out. Your job is to gently release this tab, allowing the pin to slide out.

This is where your trusty depinning tool comes in. The tool is designed to slip into the connector and push down on the locking tab, freeing the pin. The tricky part is knowing where to insert the tool. Examine the connector closely, and you'll usually see a small opening next to each pin. This is where the depinning tool needs to go.

If you're having trouble seeing the locking mechanism, don't be afraid to consult the connector's datasheet. These datasheets often have detailed diagrams showing the connector's internal structure. A little research can save you a lot of headaches (and broken connectors).

Remember, patience is key. Don't force anything. If the pin isn't releasing easily, double-check that you're using the correct depinning tool and that you're inserting it in the right place. Sometimes, a gentle wiggle can help dislodge a stubborn pin, but avoid excessive force.

4. The Extraction Process

Once you've released the locking mechanism, the pin should slide out fairly easily. Use your tweezers to gently pull the pin from the back of the connector. Avoid pulling on the wire itself, as this can damage the crimp connection.

If the pin is still stuck, double-check that the locking mechanism is fully released. You might need to wiggle the depinning tool slightly to ensure it's properly depressing the tab. Again, patience is crucial. Rushing the process can lead to bent pins and damaged connectors.

After you extract the pin, carefully examine it to make sure it's not damaged. Look for bent pins or broken crimps. If the pin is damaged, you'll need to replace it with a new one. Fortunately, replacement pins are usually readily available.

Repeat the process for any other pins you need to remove. Keep track of which pin came from which position in the connector. This will make it easier to reassemble the connector later. Consider taking pictures or making a diagram to help you remember the pin arrangement.

5. Troubleshooting Common Problems

Even with the right tools and techniques, things can sometimes go wrong. Pins can get bent, connectors can get damaged, and frustration levels can rise. But don't despair! Here are a few common problems and how to deal with them.

If a pin is bent, you might be able to carefully straighten it using a pair of fine-tipped tweezers. However, be extremely gentle, as bending the pin back and forth can weaken it and cause it to break. If the pin is severely bent, it's best to replace it.

If the connector itself is damaged, you might need to replace the entire connector. This can be a bit more involved, as you'll need to desolder the old connector and solder in a new one. But with a little practice, it's a manageable task.

And sometimes, despite your best efforts, a pin simply refuses to budge. In this case, it might be best to cut the wire and leave the pin in the connector. This is a last resort, but it's better than risking further damage to the connector or yourself.

How To DePin AMP MultiLock Connectors Toyota Connector (Using

Care and Maintenance

6. Preventative Measures

The best way to avoid the frustration of extracting connector pins is to take good care of your connectors in the first place. Avoid excessive bending or twisting of the wires, and keep the connectors clean and dry. Moisture and dirt can corrode the pins and make them more difficult to remove.

When connecting and disconnecting connectors, always use gentle force. Avoid yanking or pulling on the wires. Instead, grip the connector body and gently rock it back and forth until it releases. This will prevent damage to the pins and the connector itself.

Consider using dielectric grease on the connector pins. This grease helps to prevent corrosion and makes it easier to connect and disconnect the connectors. Just be sure to use a grease that is specifically designed for electronic connectors.

Proper storage can also extend the life of your connectors. Store them in a dry, dust-free environment. If you're storing connectors for a long period of time, consider using anti-static bags to protect them from static electricity.

FAQ

7. Q

A: While a dedicated tool is highly recommended, in a pinch, you might be able to use a very small flat-head screwdriver or a sturdy needle. However, be extremely careful not to damage the connector or bend the pins. The proper tool makes all the difference, though.

8. Q

A: The best way is to consult the connector's datasheet. These datasheets usually specify the correct depinning tool. You can also try searching online forums or contacting the connector manufacturer for advice. Often, a visual comparison can help you identify the right tool. Match the tool's tip shape to the connector's opening.

9. Q

A: Yes, usually you can. Inspect the pin closely for any damage. If it's bent or corroded, it's best to replace it. If it's in good condition, you can reuse it, but be sure to properly crimp it onto the wire.