Beautiful Work Info About Is VFD A Controller

So, Is a VFD Actually a Controller? Let's Clear the Air!

1. What Exactly Is a VFD Anyway?

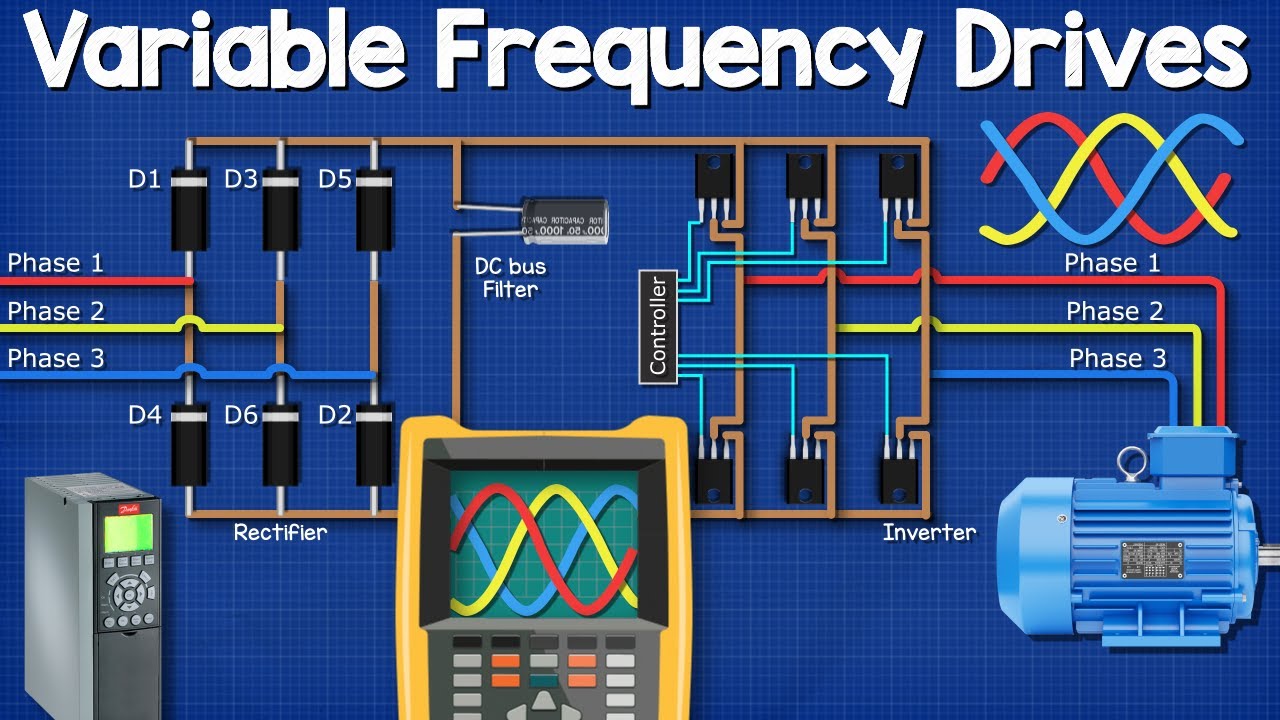

Okay, before we dive into the deep end, let's get everyone on the same page. VFD stands for Variable Frequency Drive. Sounds fancy, right? Basically, it's a device that controls the speed of an AC (alternating current) electric motor by varying the frequency and voltage supplied to it. Think of it as a dimmer switch, but instead of light, it controls the spin of a motor. Why would you want to do this? Well, that's where the fun begins.

Imagine you're driving a car. You don't always need to go full speed, right? Sometimes you need to slow down, sometimes you need to speed up. A VFD does the same thing for motors. It allows you to match the motor's speed to the actual requirements of the application, which can save energy and improve efficiency. No more wasting power running a motor at full blast when you only need it to be chugging along at half speed!

They are found everywhere, from simple fan applications in your home's HVAC system to complex industrial processes. Anywhere a motor needs to have its speed adjusted for optimal performance, you'll likely find a VFD lurking nearby. They're the unsung heroes of the motor world, quietly making things run smoother and more efficiently. Think of them as the conductors of the motor orchestra!

And it's not just about speed; VFDs can also provide features like soft starting, which reduces the mechanical stress on the motor and connected equipment. This extends the life of your machinery and avoids those jarring starts and stops that can really put a strain on things. Smooth starts, smooth stops, and precise speed control thats what VFDs bring to the table.

Is It Just a Controller, or Is There More to It?

2. More Than Meets the Eye

So, back to the original question: is a VFD a controller? The simple answer is yes, but it's a bit more complex than just a simple on/off switch. It's like saying a smartphone is just a phone. Sure, it makes calls, but it also does about a million other things. A VFD does more than just control speed; it protects the motor, monitors performance, and can even communicate with other devices.

Think of a VFD as a mini-computer dedicated to managing a motor. It's constantly monitoring things like voltage, current, and temperature to make sure the motor is operating within safe limits. If something goes wrong — say, the motor starts to overheat — the VFD can shut it down to prevent damage. It's like a built-in bodyguard for your motor, always watching out for potential problems.

They also often have sophisticated control algorithms that allow for precise speed and torque control. This is particularly important in applications where precise positioning or tension control is required, such as in manufacturing or material handling. The VFD ensures that the motor delivers the exact performance needed, no more, no less. This means more efficient processes, reduced waste, and better overall performance.

And the modern VFDs can communicate with other systems using protocols like Ethernet, Modbus, and Profibus. This allows them to be integrated into larger automation systems, where they can be remotely controlled and monitored. This is a game-changer for industries that need to manage multiple motors and processes from a central location. Imagine controlling an entire factory's worth of motors from a single dashboard!

VFDs vs. Other Types of Motor Controllers

3. The Controller Family

Now, lets put VFDs in perspective. There are other ways to control a motor, right? You have your basic on/off switches (also known as across-the-line or Direct-On-Line starters), soft starters, and even older technologies like wound rotor starters. So, how does a VFD stack up against these other options?

Well, the biggest difference is the level of control. A DOL starter basically just slams the motor on at full voltage. This is fine for some applications, but it can cause a huge inrush of current, which can stress the motor and the electrical system. Soft starters are a step up, using things like resistors or autotransformers to gradually ramp up the voltage to the motor, reducing the inrush current.

But a VFD goes way beyond that. It not only controls the inrush current, but it also allows you to continuously adjust the motor's speed and torque. This level of control is simply not possible with other types of starters. So, while a DOL starter is like a caveman club, and a soft starter is like a sophisticated hammer, the VFD is like a precision laser tool, offering unmatched control and flexibility.

Consider the energy savings, too. With a DOL starter, the motor is always running at full speed, even if it doesn't need to. This wastes energy and increases operating costs. A VFD, on the other hand, allows you to match the motor's speed to the actual demand, saving energy and reducing your carbon footprint. It's like having a smart thermostat for your motor, automatically adjusting the speed to optimize efficiency.

Why the "Controller" Label Matters (Or Doesn't!)

4. The Semantics Game

Okay, let's get a bit philosophical for a moment. Does it really matter if we call a VFD a "controller"? In a practical sense, yes and no. For someone who is simply looking for a way to start and stop a motor, a DOL starter might be sufficient, and they might not need to worry about the nuances of VFDs. However, for anyone who needs precise speed control, energy savings, or advanced motor protection, the "controller" label really doesn't quite cover the full scope of what a VFD offers.

The term "controller" doesn't fully convey the intelligence and capabilities of a VFD. It's more than just a device that turns something on and off or adjusts a setting. It's a sophisticated piece of equipment that optimizes motor performance, protects the motor, and can even communicate with other systems. It's a smart controller, if you will.

When you're searching online for solutions, understanding that a VFD is a type of controller is crucial. It will help you narrow down your search and find the right product for your needs. However, don't just stop there. Dig deeper and learn about the specific features and benefits of VFDs to see if they're the right fit for your application. It's like knowing that a hammer is a tool, but also knowing that there are different types of hammers for different jobs.

The terminology matters in the context of automation and industrial processes. A VFD acting as a controller within a larger system needs to be understood not just as a speed regulator, but as a critical component affecting overall system performance, efficiency, and reliability. It highlights that a VFD isn't just about driving motors; it's about orchestrating the entire process around it.

VFDs

5. Beyond the Factory Floor

You might be thinking, "Okay, this is all interesting, but I don't work in a factory. Why should I care about VFDs?" Well, you might be surprised to learn that VFDs are used in a lot more places than you think. They're becoming increasingly common in everyday applications, from HVAC systems in homes and offices to pumps in water treatment plants.

Think about the fan in your air conditioner or furnace. Many modern HVAC systems use VFDs to control the fan speed, which allows them to deliver just the right amount of airflow to maintain a comfortable temperature. This saves energy and reduces noise, making your home or office more comfortable and efficient. They are also commonly found in water pumps, allowing them to adjust the flow rate to meet the demand, saving energy and reducing wear and tear on the pump.

They are even found in elevators, controlling the speed and smoothness of the ride. And as electric vehicles become more popular, VFDs will play an even bigger role, controlling the speed and torque of the electric motor that powers the vehicle. They're essentially the brains behind the electric car's drivetrain, ensuring smooth acceleration and efficient energy usage.

So, the next time you're enjoying a comfortable temperature in your home, riding in an elevator, or driving an electric car, take a moment to appreciate the unsung heroes of the motor world — the VFDs. They're quietly working behind the scenes to make our lives more comfortable, efficient, and sustainable. They're the invisible hand that's shaping the future of motor control.

Unitronics VFDs

FAQ

6. Your Burning Questions Answered

Still have questions about VFDs? Here are a few frequently asked questions to help clear things up:

Q: What are the benefits of using a VFD?

A: VFDs offer a range of benefits, including energy savings, improved motor control, reduced mechanical stress, extended equipment life, and increased process efficiency. They allow you to match the motor's speed to the actual demand, saving energy and reducing wear and tear.

Q: Are VFDs difficult to install and maintain?

A: Modern VFDs are designed to be relatively easy to install and maintain. However, it's important to follow the manufacturer's instructions and to have a qualified electrician perform the installation. Routine maintenance typically involves checking connections, cleaning the unit, and monitoring performance.

Q: How do I choose the right VFD for my application?

A: Choosing the right VFD depends on a number of factors, including the motor's horsepower, voltage, and current requirements, as well as the specific application and operating conditions. It's best to consult with a VFD supplier or a qualified engineer to ensure that you select the appropriate VFD for your needs.

Q: Can a VFD be used with any motor?

A: While VFDs are primarily designed for AC induction motors, they can be used with other types of motors with appropriate adjustments and configurations. It is essential to verify the compatibility between the VFD and the motor to ensure optimal performance and prevent damage.